Could Silverbrook's stunning Memjet inkjet be a hoax? This article looks at a few of the arguments from people who say that Silverbrook Research's impressive demonstration videos* of the one page per second inkjet cannot possibly be real.

Since this is an opinion piece, let's just put our cards on the table right away. Could Memjet be a hoax? No, we really don't think so. A great demonstration isn't the same as a finished product, we admit, but we believe the videos show fully working prototypes, just as Silverbrook Research has claimed.

We're convinced for three key reasons: the strong endorsement Silverbrook has received from Lyra Research, the leading imaging industry analysis firm; the track record of the scientists working at Silverbrook Research, particularly founder Kia Silverbrook; and lastly the towering stack of 3500 patents and patent applications that the company has piled up. We'll refer mainly to those documents in this article.

Yes, but...

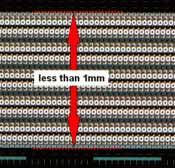

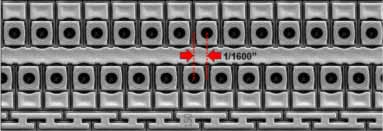

Many people have pointed out that fast printing speed alone isn't enough to make a fast printer. The 1600 DPI printheads can produce two and a half million dots per square inch. You need to feed a huge amount of image data to the printer very quickly - about 220 Megabits per second for an A4 or letter-size page. If you can't, the printer will be slower because it will have to wait for the data.

Many more have asked how a fixed inkjet printhead with extremely narrow ink nozzles can cope with the clogging and blockages that seem to be a standard feature of inkjet printers.

We'll look at some of the technology that Silverbrook Research claims can overcome those problems.

By the way, this article will be much easier to understand if you've read some of Texyt's previous stories, which explain how the Memjet printhead is put together, examine the printing quality, and include a video of the prototypes.

More Inventions

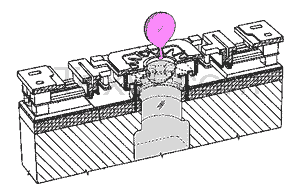

Silverbrook's solution to both the challenges mentioned above depends on yet more inventions. One is the SoPEC chip (Small office home office Print Engine Controller). This is a computer on a chip, with a LEON SPARC CPU core, 2.5 megabytes of DRAM, USB 2.0 controllers, and interfaces for the printer's feed motor and printheads.

Silverbrook's solution to both the challenges mentioned above depends on yet more inventions. One is the SoPEC chip (Small office home office Print Engine Controller). This is a computer on a chip, with a LEON SPARC CPU core, 2.5 megabytes of DRAM, USB 2.0 controllers, and interfaces for the printer's feed motor and printheads.

The SoPEC chip in the prototypes is an ASIC (Application Specific Integrated Circuit) designed by Silverbrook Research and manufactured by Magnachip at one of its fabs in South Korea*. See the photo on the right. Incidentally, the printheads are fabbed by TSMC in Taiwan, according to Lyra. (Update May 28: According to Memjet, the SoPEC chip is now being manufactured by IBM. Some sources claim that, although TSMC is involved in manufacturing, another Taiwanese firm will fab the micro-electromechanical part of the printhead).

“The driver chip is an integrated printing system on a chip that efficiently manages and processes large quantities of data, a page at a time, and drives the printheads in real time, calculating up to 900 million drops per second,” according to Silverbrook.

The SoPEC chip has three very interesting features.

-

A hardware JPEG decompressor

-

Two or more chips can be linked together to work together on the same print job

-

Firmware to compensate for 'dead' ink nozzles and misaligned print heads.

But 1600 nozzles per inch will get clogged up?

Before taking a closer look at the SoPEC controller chip, let's examine Silverbrook's answers to the problem of clogged ink nozzles on the print head. This is by far the leading cause of failure of current inkjets. If the printer doesn't get used often enough, the ink dries and sets hard inside the hair-thin nozzles. There's often no way to remove it without damaging the very delicate print head.

Before taking a closer look at the SoPEC controller chip, let's examine Silverbrook's answers to the problem of clogged ink nozzles on the print head. This is by far the leading cause of failure of current inkjets. If the printer doesn't get used often enough, the ink dries and sets hard inside the hair-thin nozzles. There's often no way to remove it without damaging the very delicate print head.

The Memjet A4/Letter size printer has more than 70,000 ink nozzles on its print head. Keeping all those nozzles unblocked sounds like an impossible task. Not only can the ink block them if it dries, but fine particles of paper and dust can, too.

Silverbrook has patented several different technologies that its researchers believe can deal with these problems. We don't know which of them are being used in the prototype printers.

Painting the sky in red and yellow

The amount of ink moving through each nozzle is so small that they may actually begin to dry out during printing if they're not used. Silverbrook has a way of dealing with this: make sure that all the nozzles get used every time a page is printed.

So your nice photo of a blue sky is going to end up spattered with thousands of red and yellow dots? Yes, that's correct.

But at 1600 DPI, they're too small to see as long as they're evenly scattered over the whole page, the company claims. Sounds unbelievable? Bear in mind that about 100 drops of ink from the Memjet print head would fit into the dot at the end of this sentence.

Doesn't this waste a ridiculous amount of ink? There are more than 70,000 nozzles on the print head, and we're going to shoot ink out of all of them every time we print a page!

Actually, the total amount of ink used if you fire every nozzle on the print head is about 0.00007 ml. That's because the ink drop size is only about one picolitre (a billionth of a milliletre). So you would have to print at least 15,000 A4 pages before you had wasted one ml of ink The Memjet A4/letter reference design calls for an ink cartridge holding 50 ml.

An ink drop is very cheap

So firing out thousands of extra ink drops is inconsequential. That's why Silverbrook has also patented a system for clearing nozzles which are already blocked, by warming them and pushing ink into them at high frequency. We'll take another look at that technology later in this article.

Further inventions to protect the printhead include a cap that covers it as soon as it stops printing. And there's also a pump that produces compressed air to blow any unwanted material away from it while it's printing. Silverbrook's patents even describe a system that uses the same air pump to push moistened air under the cap, to prevent the printhead from drying out when it's not used for a while.

We understand that compressed air may also be used to provide pressure to push ink through the long path from the cartridges through to the heating chambers that will fire the ink out of the nozzle and onto the paper.

SoPEC: one chip, 40 million transistors

With the sophisticated SoPEC chip, Silverbrook's printer concept has the CPU muscle to process all the incoming data on the fly, the company says. The maximum amount of data that needs to be fed to the printer, more than 200 Mb per second, exceeds the real world performance of typical USB 2 links, so compression is used. JPEG is well suited to squashing color photos and similar images.

JPEG isn't so efficient for text or line drawings. It appears that Silverbrook's driver figures out how best to compress different areas of a page, and uses a more suitable compression algorithm for text and line drawings.

The SoPEC ASIC has a lossless decompression module, or firmware, to handle this (unlike JPEG, such algorithms don't require complex floating-point calculations). The compression scheme used, SMG, is in fact a modified version of the group 4 compression used by fax machines. The printers do not print text by storing font files or transferring fonts from a host PC.

Since the two megabytes of memory on the chip won't always be enough to store the whole page, even compressed, the driver software feeds more compressed data to the printer as the page is emerging. The printer apparently cannot stop in the middle of a page and restart. We suspect this may be due to the risk of the ink nozzles drying out, among other issues.

Dead Nozzle? No problem

The most interesting feature of the SoPEC chip is it's ability to compensate for dead ink nozzles. For example, the chip's firmware can boost some of the ink dots around a dead nozzle to partially disguise it. So, if a yellow nozzle is missing, it fires some extra yellow from adjacent yellow nozzles.

Doesn't this mean you'll see a long, white line through the image? Probably not. Once again, an essential point to remember is that we're talking about a dot resolution of 1600 dots per inch, so that white line will be less than 16 microns wide – one seventh the width of a strand of hair, and it will be obscured by adjacent inkdrops spreading out. Silverbrook is aided by the fact that human color vision just isn't very sharp.

Doesn't this mean you'll see a long, white line through the image? Probably not. Once again, an essential point to remember is that we're talking about a dot resolution of 1600 dots per inch, so that white line will be less than 16 microns wide – one seventh the width of a strand of hair, and it will be obscured by adjacent inkdrops spreading out. Silverbrook is aided by the fact that human color vision just isn't very sharp.

If you're familiar with the idea of hard disk drives or flash memory chips which mark bad sectors and stop using them, then this is similar. In fact, like some disk drives, the printhead appears to actually contain some spare nozzles, which are positioned to take up the slack when nozzles in front of them have failed.

A single SoPEC chip's dead nozzle correction unit has enough memory to handle cases where at least 5 percent of all the nozzles on the printhead are dead. So it seems that Silverbrook's researchers believe the printed output will still be acceptable with that level of nozzle failure or blockage.

How does the printer detect a dead nozzle? Well, strangely enough, it can't – according to some of Silverbrook's statements in patent applications - even though such a feature would seem to be an ideal way to deal with clogged ink nozzles and keep the printer running.

Strange patents

Several of Silverbrook's patents, rather oddly, go out of their way to assert that the print head doesn't contain any circuits to detect a faulty nozzle. This is very curious, because patents normally describe what an invention can do, they don't bother listing what it can't do. We've heard of companies being intentionally misleading in patents before, to confuse imitators. Could that be what's going on here?

What's particularly odd is that Silverbrook has patented a printhead design with individual thermal sensors on each nozzle, to detect overheating, and in fact, clogged nozzles do tend to overheat. Even more bizarrely, that very same patent also contains the company's apparently contradictory claim that the printhead contains no temperature sensor or blocked nozzle detector. More about this at the end of the article.

What's particularly odd is that Silverbrook has patented a printhead design with individual thermal sensors on each nozzle, to detect overheating, and in fact, clogged nozzles do tend to overheat. Even more bizarrely, that very same patent also contains the company's apparently contradictory claim that the printhead contains no temperature sensor or blocked nozzle detector. More about this at the end of the article.

According to the patents, the dead nozzle compensation system seems to have two functions. One is to help handle printhead misalignment.

The Memjet printhead is made up of many 20 mm long sections, fitted together in a kind of jigsaw puzzle. The SoPEC chip can compensate for any that are slightly out of position. So-called 'dead' nozzles occur when there's a small gap between two sections of the head – a nozzle isn't where it should be.

We're going to speculate again, and guess that the printer prints out some test patterns after it comes off the production line, and these are used to fill in the dead nozzle map, and calibrate the controller chip to match the inaccuracies in the print head. It seems obvious that, if this happens, any genuinely dead nozzles will also be included. (Further examination of the patents since this story was originally written suggests that this guess is at least partly correct.)

This will greatly improve the production yields of the Memjet printhead fabrication process, since slightly faulty print head sections won't need to be discarded - and minor errors in assembly of the printhead can be compensated for.

We'll take another little step into speculation here and say 'why couldn't we use the same method to recalibrate the print heads after they've been in use for a while'? Perhaps when they begin to become blocked, and the printing quality deteriorates. A self-repairing print head? In fact, at least one of the patents does say that a printer's dead nozzle map can be updated at any time.

The print head that repairs itself?

.jpg) We believe that if three of the Silverbrook Research inventions were combined, they might produce a self-healing printhead. They are

We believe that if three of the Silverbrook Research inventions were combined, they might produce a self-healing printhead. They are

1. The thermal sensors on each nozzle

2. The blocked nozzle unclogging system

3. The dead nozzle correction unit

The thermal sensors can detect blocked ink nozzles. In the current Memjet inkjet design, a blocked nozzle will begin to heat up because it can't expel the heated droplet of ink it produces when fired.

The blocked nozzle unclogging system can respond to this by pulsing the nozzle at high frequency, to attempt to unblock it. The cleaning frequency used, incidentally, is 17KHz, which is very close to ultrasound cleaning frequencies.

If this fails, and temperature continues to rise, the SoPEC chip can add the nozzle to its list of dead nozzles, and stop using it. The SoPEC chip can compensate for the dead nozzle in future - it's designed to handle at least 5 percent nozzle failure on the print head.

However, although the technology appears to be in place, according to the patents, we were unable to find a patent or patent application where Silverbrook has linked these three systems together in this way. Although with 3500 to look through, we wouldn't be surprised if it's in there somewhere.

March 24: This article has been substantially updated with new information, corrections and clarifications.

March 31: Added note on dead nozzle map update capability mentioned in patents.

*Update April 2: Since this story was written, Memjet Technologies has removed all video of the wide format printer from its website. The company also removed another video which showed all four of its prototypes, including the wide format printer. However individual videos of the other three protoypes, an A4/Letter printer, label printer, and a photo printer, remain on the site. We don't yet know why Memjet removed the video of the wide format printer - see May 28 update also.

Update May 28: Memjet has added a new video of its wide format printer prototype to its site.

*We earlier incorrectly identified the chip maker, as either Hynix, from which Magnachip was spun off in 2004, or Hynix's former parent firm, Hyundai.

NO cables and no paper in the printer video

very nice but you've not answered two enormous questions that everyone whose seen those videos asked. How funny and convenient...

WHY THERE ARE NO CABLE GOING IN TO THE PRINTERS IN THE VIDEOS??

WHY WE CANT SEE The BLANK PAPER GOING IN??

i know you'll delete this but u aught to know thar people are'nt stupid

Antonio

Laughable and ignorant objections

I find a couple of the objections and reasons why this thing must be fake to be somewhat laughable and ignorant.

I am a commercial Photographer and if you asked me to photograph or video ANY product that had cords coming out the back, I would do my best to hide them....any commercial photographer would. Have a look in any electrical appliance catalouge and tell me how many cords you see coming out of the Steam irons or electrical kettles. You won't see them so they must be fake too. Cords are messy things that are irrelevant to the product so at best, with them not being shown in the video, I would say that it was done by someone with some professional or commercial experience. It is simply not professional practice to leave cords in promotional or advertising images.

The other thing is transfer speed with USB or whatever.

I have run wide format Photographic LAMBDA machines ( anyone heard of these?) and they do not start printing untill a buffer in a computer that runs the thing has been filled and the machine has warmed up it's lasers etc. In wide format mode, although these machines are reasonably slow, you could not transfer the data fast enough for the info to be sufficent for the paper width being printed. The machines run in batch mode because of this so I see no reason these printers could not do the same. With the price of flash memory and the like now, having a gig of ram built in on a manufacturing scale would cost penuts.

Just because the data transfer may be slow, dosen't mean the printer output has to be.

First off you can see the

First off you can see the shadow of the cord in the video of the A4 style. A cord running through the video would be ugly so they ran it off the back out of sight.

Look at the bottom top right corner of what appears to be the loading tray and you'll see a thinning white line that is the top of the papers.

cables and paper

Antonio,

First,it is not "aught" it is "ought".

Second,it is "arn't" not "are'nt" for "are not".

Third,read what the photogapher wrote.Makes sense to me.

Just thought you would like to know.

Keep thinking.

Mike

Actually are not would turn

Actually are not would turn into aren't

LOL, good one except it's

LOL, good one except it's not are'nt it's aren't...you keep thinking

Jeez, where did you learn

Jeez, where did you learn English grammar? IT IS AREN'T!!

...and I suppose you have

...and I suppose you have seen this thing in action..?

I know it's real...

Can't see cables or paper going in. Are you BLIND?

I can't believe how many people are complaining that it can't be real because they cant see cables or paper going in. Are you BLIND?

The cables are GREY. if you look at the a4 printer, you CAN see it, in the middle on the right edge off behind the printer. As if they're going to make the cable bright yellow or something!?!

Once again, paper tray - clearly visible... underneath the out-tray. A printer this size-sensitive, you don't want the paper sitting out in a 'bypass' tray collecting dust, so of course it's contained - but it would be stupid to put the in and out trays on different sides, so it goes underneath to keep the footprint of the printer as compact as possible.

Have any of you looked at an office photocopier lately - I can see one from my office. And you know what? I can't see the paper going in blank and coming out printed there either, because its in an ENCLOSED TRAY.

I find it astounding how so many people are so convinced that the current state of technology is as good as it can possibly get, and just live with the insufficiencies of it, so much so that they're prepared to state that something that someone (and their 300 staff members) has spent 15 YEARS developing cannot be possible. Wake up people, its real, and its coming.

Check out the Lyra report.

Check out the Lyra report. They wouldn't publish if they haven't seen it!

Current inkjets are already 37 ppm, this is nothing surprising

Current inkjets like the $150 HP K550 alraedy have speeds of 37 pages per minute, this printer at 60ppm is barely twice as fast as the HP K550, and with it's printhead design I'm sure they'll be able to reach much faster speeds soon.

With low end lasers still at 4ppm, lower resolution and much higher toner cost, I can only see laser printers starting to fade away in the comming years, current inkjets ALREADY FAR surpass laser printers in virtually every aspect, they even have water resistant inkjet papers that still cost less than the toner cost per page of laser printers.

HPK550 claims 37

HPK550 claims 37 pages/minute. But that’s in draft mode with very low resolution. Where as this printer can print 60 pages/minute full colour with much higher resolution. It can only get faster!

real

I know many people who work in the company. Physicists, Chemists, computer scientists, engineers, production managers the list goes on and on. It's real.

I had the opportunity to see

I had the opportunity to see this company's facilities and prototypes approximately 3 years ago. It is real!

agreed

I also have a connection to silverbrook, and if this was a hoax it is the most expensive pointless hoax ever. There is a hell of a lot of very talented well paid people working there and they know what they are doing.

who is making this great ink

who is making this great ink for them? doesn't sound ike this is regular ink?

A compression technology

A compression technology called SMG sounds very appropriate for a machine that fires out bullets of ink at high speed!

Silverbrook Modified Group 4

Well, SMG is Silverbrook Modified Group 4 in this case, and not submachine gun, but perhaps the clash of acronyms was intentional

JM

It is really breakthrough of printer technology

Yes, many engineers of the major printer manufacture have already looked at the real demo of memjet, then supprized about the technology of memjet.

It is really first and high quality. When this technology becomes true product, the current mojor printer manufactures have the big impact. They have no way except buying memjet technology or printer head. If Silverbrook does not allow these companies to make the ink by themselves and force to but ink from him, the major printer manufacturers should have serious problem on the income.

Bob

it is a scam it should be in

it is a scam

it should be in popular mechanics

with the flying cars

Not a Scam

I know that this can not be scam, as I know people that have gone and seen this first hand, the wide format plotting is the big one they should focus on though, as it will cause major changes in all engineering and architectural firms.

Products in stores in 3Q07....

Haven't seen evidence of that one yet, and I do believe we're well into 4Q....

humorous to see the comment about Kia's 'track record'. I've followed his patents for years (read one or two at uspto.gov, you'll find mostly garbage filler) - articles I've seen on the guy say he's never built anything in 20 years.

I think you will look back on this one as a dud.

about software used for memjet printer

respected sir

i am a printing student from India, i had gone through your article of memjet technology but i didn't get specific information about software used.

so could you please give me some information about software used and the working of the memjet printer.

i am waiting for your reply.

thanking you.

regards SUNIT BAIKAR

Sounds great....I want one.......

It is now the last part of the 1st quarter - in the next year.....where can I get one? I need a fast printer now!

How Quickly Does The 1st Page Come Out?

Regardless of how many pages are shot out per minute, the time taken for the first page to print should a major consideration for users who usually print documents consisting of just a few pages.

I just purchased a rather speedy (by present standards, anyway) laser printer that puts out 21 ppm black and/or colour but the time taken waiting for the thing to warm up and print that first page can be somewhat frustrating at times.

I've spoken to a manager on

I've spoken to a manager on the software team there recently (the embedded software). He told me a few things about what they are doing at the moment, based on what he told me I'd assume they are looking to cut costs to save as much money as possible during production. To me that sounds like someone who wants to rip the market a new one. These things are going to be affordable and effective, let's hope they are reliable too!

As far as i know this technology is real, and there is a lot of research gone into it.

Real

I am an engineer working on one of these printers. They are definitely real. Kia's timelines were off, that's all.

A Laser Printer That Sucks

Did you know your laser printer may actually save you from infringing the DMCA. Yes, the Digital Millennium Copyright Act that prohibits you downloading pirated movies and software. How is that possible? Guys from University of Washington examined BitTorrent file-sharing networks using specially designed BitTorrent clients to monitor the traffic on these networks. The researchers didn’t download any files, but somehow they received over 400 takedown requests - notices from the ISP to stop distributing that copyrighted content. Best regards gq.

Your Site is good.

You are not right.

my magnificent feelingg

All greetings! I have fallen in love today:)))))

I wish to shout about love to all world ! :)

Love this magnificent feeling:)))))

printers

I think that Epson printers, the laser series, are very efficient in speed printing and of course the quality of printing... The problem is that if you more speed, the cost of such a printer increases and maybe not many of us can afford a 1000$+ printer.

Power consumption/ overheating ?

For 70,000 print heads all producing heat, the power consumption has to be high. On the image/video for the mobile phone printer, the 'black' and 'red wires' can be seen and are substantial in diameter. This may prevent any 'desktop'type application, I may be wrong, but doesn't a moving print head in a ink-jet provide some cooling? Although the technology is real, the reliability is probably the 'hoax'.

Guys... the technology is

Guys... the technology is for real bcoz i have seen the printer... its the technology of the future....

and will stay that way ....

and will stay that way ....

high failure rate to date

I worked there till recently, but left there in disgust. Having worked on this printer I can say there's a high failure rate and the print head just doesn't last. Super fast, sure, but for short while, after which streaks, blobs and all kind of print artifacts become evident and the cost of replacing the head would be about three times that of an (already expensive) inkjet head in a regular printer. That's why it's taken so long to get this thing out to the market; once they can sort the failure rate (and quality for that matter) then it may be a good printer but the price will shit you - speaking of which, the management shat me enough being so pushy and the boss (we'll call him Mr W) is just that -total wanker. I can also tell you with certainty that a /* different */ technology designed by a competitor I know will make the memjet look like a piece of junk turfed on the side of the road (which the memjet will be soon after deployment to the mass market).